7 reasons I’m switching to PETG filament for my 3D printing

PETG filament is quickly becoming my top choice due to its remarkable blend of strength and adaptability. I’ve tested various filaments in my printing journey, but I keep returning to PETG for its reliability and well-rounded performance. PLA remains popular for beginners because it’s relatively easy to work with, but it can fall short in more demanding projects.

PETG steps in with superior durability and heat tolerance, allowing you to explore your more ambitious designs without sacrificing quality.

PETG may present a few small drawbacks, but these are minor compared to its benefits. Transitioning from PLA to PETG can feel like a leap, but the payoff in the longevity, resilience, and overall quality of what you create using your 3D printer is well worth the effort.

7

Great balance of strength and flexibility

Experience prints that withstand everyday bumps and stress

PETG is known for producing parts that easily handle tension and compression. It offers a sturdier outcome than PLA, which can crack or chip when placed under significant strain. This balance between rigidity and slight bendiness ensures that your creations remain resilient over time, even when used daily. You can create anything from phone stands to custom brackets, confident they won’t snap at the first sign of pressure.

The flexibility of PETG is one of its main strengths, particularly for functional items that require a bit of give. PLA can sometimes break if twisted or struck, whereas PETG tends to spring back more effectively. If you’re designing components that endure frequent handling, PETG’s toughness helps keep them intact for more extended periods. This advantage is beneficial if you sell printed items or rely on them for work-related tasks.

A slight drawback of PETG is its tendency to produce stringing during printing, which might require extra fine-tuning of retraction settings in your slicer software. However, this minor inconvenience pales in comparison to the reliability it delivers in final prints. You’ll typically see smooth edges and minimal flaws with just a bit of tweaking and experimentation. The payoff is a functional piece that holds up better than many PLA prints in real-world conditions.

6

Enhanced durability for functional printing tasks

Rely on robust designs without frequent reprints

Choosing PETG means reducing the risk of brittle prints that need constant replacement. Its enhanced strength lets you produce durable parts that withstand mechanical stress. In many cases, you’ll notice that PETG prints do not crack easily under repeated use, allowing you to deploy them in practical projects with more confidence. This durability sets it apart from PLA, especially for items that must perform reliably over time.

Functional prints often need to withstand moderate impacts or bear specific loads without failing. With PETG’s durability, you can undertake projects ranging from custom hinges to model car components, knowing they won’t crumble unexpectedly. Over time, relying on fewer reprints can save you both material costs and frustration. The cumulative effect of consistent performance adds up, making your entire workflow more efficient.

One trade-off is that PETG can be slightly more expensive than PLA and sometimes requires a heated bed set to a higher temperature. Despite these extra considerations, the savings in reprints and wasted time quickly balance the scale. You’ll spend more initial effort refining your printer settings, but the end results last longer. This long-term reliability justifies the slight cost difference for anyone serious about dependable 3D-printed parts.

5

Higher heat tolerance over typical PLA

Keep your projects safe from excessive warmth

Source: weeeak/MakerWorld

Thanks to the higher thermal tolerance of PETG filament, this 3D-printed storage box will withstand the heat of your garage in the hot summer much better than if printed with PLA

PETG excels in conditions where PLA would warp or lose its shape. With a higher glass transition temperature, PETG resists softening when exposed to heat sources like sunlight or a warm engine compartment. This thermal stability is crucial if your prints serve a functional purpose in hotter environments. Whether you’re creating a car accessory or a part for home appliances, PETG ensures you won’t see your work buckle under moderate heat.

Even slight temperature increases can degrade PLA near its heat threshold, causing deformation or sagging. PETG’s resilience alleviates this worry, making it suitable for projects with occasional exposure to hot surfaces. This characteristic allows you to expand your printing horizons and produce items that withstand real-world temperature fluctuations without compromising quality. This advantage translates directly into more dependable results.

The downside is that PETG needs a bit more attention during the cooling process to maintain a smooth finish. Proper fan speed settings help maintain both dimensional accuracy and surface quality. Although this step may seem extra initially, it lets you take advantage of PETG’s superior heat resistance. With slight adjustments to your slicer profile, you’ll discover it’s more than worth the effort.

4

Impressive chemical and moisture resistance

Safeguard printed items in challenging environmental conditions

Source: BATTCAVE/MakerWorld

Using PETG makes these containers much more airtight and waterproof

Many makers appreciate PETG’s ability to withstand humidity and exposure to various chemicals better than PLA. If you’re crafting containers or parts used in slightly corrosive or wet settings, PETG’s composition offers an extra layer of protection. This feature can make a big difference when your printed objects regularly come into contact with cleaning agents or outdoor elements. Having that peace of mind can encourage you to pursue projects you might otherwise avoid with PLA.

PETG typically endures in damp areas without compromising structural integrity due to its lower tendency to absorb moisture. PLA, on the other hand, can degrade over time when exposed to water or humid conditions. By switching to PETG, you gain extra security for items like planters, tool handles, or specialized machine parts that might face different environmental challenges. It’s a flexible solution for those who work on multifaceted projects.

PETG requires careful storage, as dust or debris on the filament can impact the final product’s appearance. Keeping your filament sealed and clean becomes vital if you want perfectly smooth results. However, these minor organizational steps are not difficult to implement. The added protection PETG provides against moisture and chemicals generally outweighs the slight inconveniences of managing your printing space.

3

Less warping and minimal odor output

Print comfortably without pesky curling or fumes

One of PETG’s key advantages is its lower rate of warping compared to PLA. Warping can lead to curved edges that ruin the dimensional accuracy of your prints. When you use the correct temperatures and adhesives, PETG often adheres well to the print bed, helping you avoid that disappointing curled-up base. By reducing the likelihood of failed prints, PETG saves you time and lessens the aggravation of constantly adjusting your setup.

PETG also emits less odor during printing, creating a more pleasant environment if you work in a confined area. PLA is generally considered low-odor, but specific blends can still produce a noticeable smell. PETG’s milder fumes are a welcome bonus for anyone who prints frequently or in shared workspaces. A more comfortable workspace can contribute to smoother and more focused printing sessions.

Occasionally, PETG might stick too firmly to the bed, making removal challenging. Finding the sweet spot in bed preparation and temperature settings is important to avoid damaging your print or the build surface. With a bit of experimentation, you’ll be able to strike the right balance, retaining PETG’s minimal warping benefits. Reducing curling and odor is worth the effort, especially if you prioritize a more stable and user-friendly printing process.

2

Easy post-processing for polished results

Craft professional-looking pieces in less time

PETG’s smooth finish out of the printer often requires minimal sanding or other post-processing steps. Prints look glossy or have a subtle sheen that can pass for a finished product without too much extra work. If you’ve ever spent hours smoothing out PLA prints, you’ll likely appreciate the simpler finishing routines PETG enables. This time-saving benefit can motivate you to produce more elaborate or detailed designs.

Even intricate pieces benefit from PETG’s lower tendency to highlight layer lines. The material maintains decent clarity and surface uniformity, making your printed objects look professional. When painting or adding finishes, PETG holds up well and usually absorbs these treatments evenly. This adaptability makes the transition from raw print to final piece more straightforward.

However, PETG can string more than PLA during printing, which might lead to fine wisps of filament between parts of your model. Although it’s a small hurdle, dealing with highly detailed models can increase your post-processing workload. Adjusting your retraction and temperature settings typically lessens this effect, and the overall finishing still remains comparatively straightforward. In most cases, you’ll find that the simpler sanding and coating process more than makes up for a few extra filaments to snip away.

1

Versatile design choices and printing possibilities

Unlock creative freedom with fewer material limitations

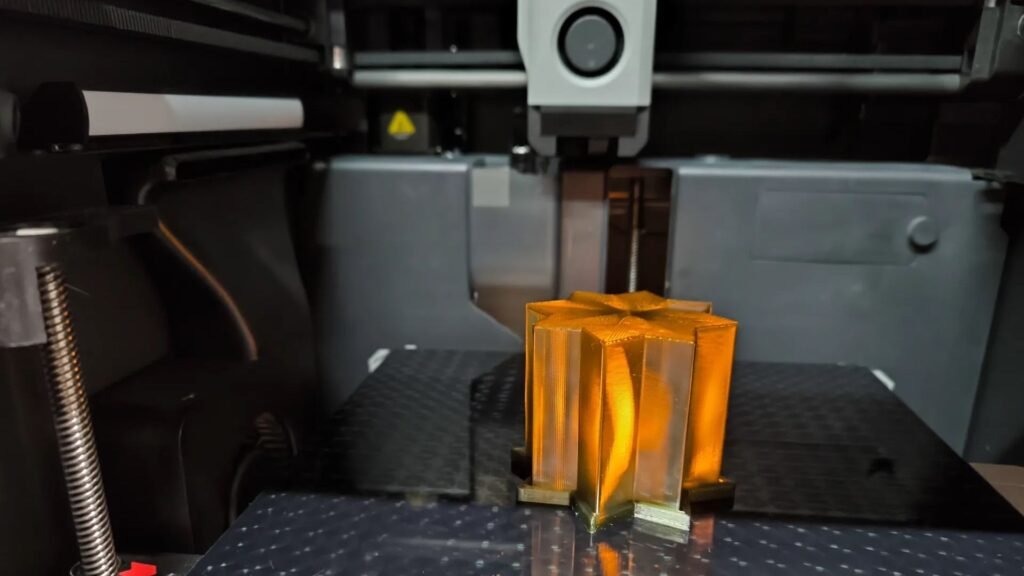

PETG shines in a broad spectrum of projects, whether you’re experimenting with functional parts or designing decorative items. Unlike PLA, which can be limited due to its lower heat resistance and sturdier brittleness, PETG confidently takes on more challenging tasks. It bridges the gap between ABS-level strength and PLA-level printability, producing a material that works well across different design demands. This adaptability can spark newfound inspiration for your creative pursuits.

You can select from various PETG blends and colors, including transparent or translucent options. These unique variants allow you to craft eye-catching models that capture light or show off interior components. This visual advantage means you can produce decorative pieces that stand out in addition to the purely functional parts that PETG excels at. The material’s broad appeal suits hobbyists who enjoy pushing their creativity to new heights.

The only real caution here is that PETG can require a slightly slower print speed than PLA to ensure precise layers. If you’re in a rush, the extended print times might be inconvenient. However, the payoff is a material that consistently delivers sturdier, more flexible prints. By accommodating these print settings, you’ll open yourself up to a material that is more than capable of bringing your boldest ideas to life.

Look ahead to stronger, more versatile prints

Switching from PLA to PETG offers a range of clear advantages that elevate your 3D printing experience. Although it requires careful calibration, PETG provides superior durability, heat resistance, and chemical resilience. Over time, the minimal warping, low odor, and flexible design options will help you tackle more ambitious projects more confidently. By accepting the slight learning curve and higher material cost, you’ll likely find that PETG more than compensates with its stable, long-lasting results. Embracing these benefits sets you toward consistently reliable prints that fully realize your creative and practical goals.