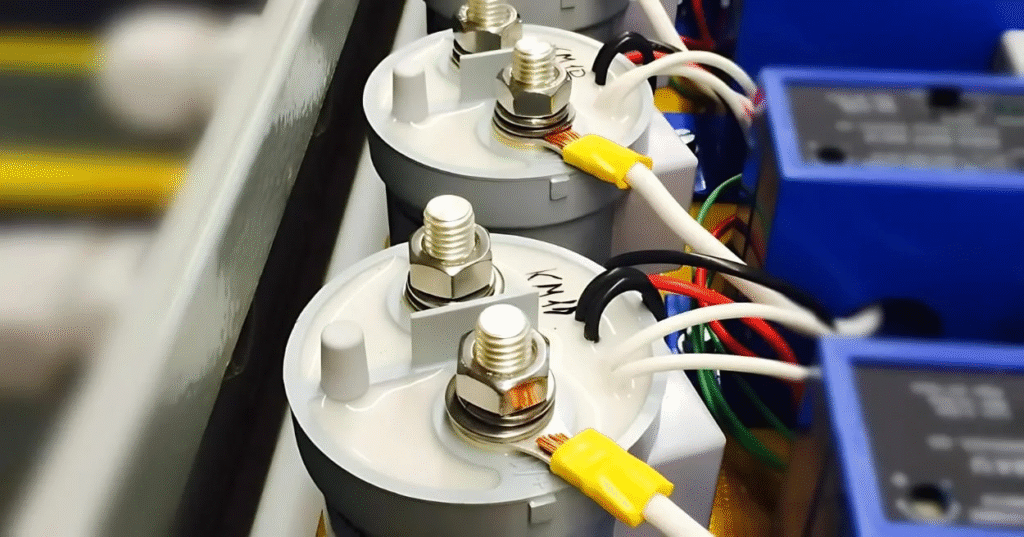

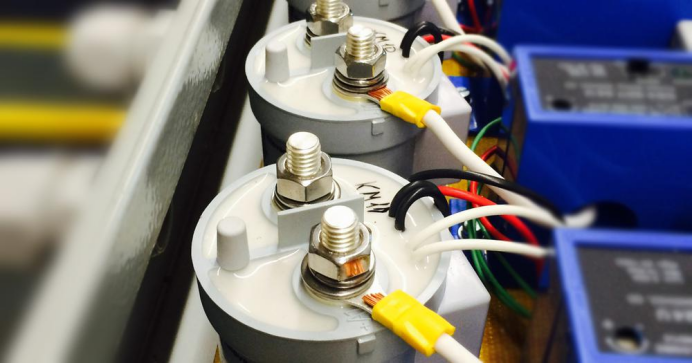

High Voltage Resin DC Contactors: The Value-Driven Safety Solution

The electric revolution is reshaping industries worldwide, and at the heart of this transformation lies a critical component: high voltage DC contactors. As power systems evolve toward higher efficiency and greater reliability, the choice of switching technology becomes increasingly important. Among the available solutions, High Voltage DC Relays with resin construction are emerging as the intelligent choice for demanding applications across multiple sectors.

Resin-encapsulated high voltage DC contactors represent a breakthrough in practical engineering, combining robust performance with exceptional versatility. The advanced resin technology delivers a unique combination of environmental protection, compact design, and cost-effectiveness that traditional solutions struggle to match. For organizations seeking reliable switching solutions without compromising on quality, high voltage DC contactors with resin construction offer the perfect balance of performance and value.

What distinguishes resin contactors in today’s competitive market is their remarkable adaptability to diverse operating conditions. The sealed resin construction provides unparalleled protection against moisture, dust, and chemical exposure—challenges that frequently compromise conventional switching equipment in real-world applications.

Superior Environmental Protection

Moisture and Corrosion Resistance

High Voltage DC Contactors featuring resin encapsulation excel in environments where moisture and corrosive elements threaten equipment reliability. The hermetically sealed resin housing creates an impenetrable barrier against water ingress, salt spray, and chemical contaminants. This makes resin contactors the preferred solution for outdoor installations, coastal facilities, and industrial environments with aggressive atmospheres.

Marine applications, offshore wind farms, and chemical processing plants particularly benefit from this superior environmental resistance. Where other technologies require expensive protective enclosures, resin contactors deliver built-in protection that reduces installation complexity and total system costs.

Dust and Particulate Protection

Industrial environments often generate substantial dust and particulate matter that can infiltrate switching equipment, causing premature failure. The complete resin encapsulation eliminates internal contamination risks, ensuring consistent performance even in the harshest conditions. Manufacturing facilities, mining operations, and construction equipment applications rely on this robust protection for uninterrupted operation.

Compact Design for Space-Constrained Applications

Optimized Footprint

Modern applications increasingly demand higher power density in smaller packages. High Voltage DC Relays with resin construction deliver exceptional power handling capabilities within remarkably compact dimensions. This space efficiency proves invaluable in electric vehicle applications, where every cubic centimeter matters for overall vehicle design and performance.

The reduced footprint enables more flexible system layouts, simplified cable routing, and improved thermal management in tight spaces. Equipment manufacturers appreciate how resin contactors facilitate innovative product designs without sacrificing electrical performance or safety margins.

Weight Optimization

Beyond dimensional advantages, resin contactors offer significant weight savings compared to ceramic alternatives. This becomes critical in mobile applications—from electric vehicles to aerospace systems—where every kilogram affects efficiency and performance. The lightweight construction reduces structural requirements and improves overall system efficiency without compromising reliability.

Cost-Effective Performance

Manufacturing Efficiency

The production process for resin-encapsulated contactors enables cost efficiencies that translate directly to customer value. Advanced manufacturing techniques deliver consistent quality while maintaining competitive pricing, making high-performance switching technology accessible to a broader range of applications and budgets.

This economic advantage doesn’t mean compromising on quality. Resin contactors meet the same rigorous performance standards as premium alternatives while offering superior value for high-volume applications and cost-sensitive projects.

Reduced Installation and Maintenance Costs

The sealed construction of resin contactors eliminates the need for additional protective measures during installation. This simplifies deployment procedures, reduces installation time, and lowers labor costs. The inherent environmental protection also extends maintenance intervals, reducing lifecycle costs and improving overall return on investment.

Versatile Application Range

Electric Vehicle Systems

The electric vehicle industry has embraced resin contactors for their combination of compact size, light weight, and reliable performance. From battery management systems to charging infrastructure, resin technology provides the switching capability that modern EVs demand while meeting stringent automotive reliability standards.

Renewable Energy Integration

Solar and wind installations benefit from the weather-resistant properties of resin contactors. These components handle the daily switching cycles required for optimal energy management while withstanding outdoor exposure for decades of reliable service.

Industrial Automation

Manufacturing facilities and automated systems leverage resin contactors for their dependable performance in diverse industrial environments. The combination of environmental protection and compact design makes them ideal for robotic systems, automated guided vehicles, and process control applications.

Technical Excellence Meets Practical Value

High Voltage DC Relays with resin construction don’t just meet specifications—they exceed real-world performance expectations. The technology delivers measurable advantages in installation flexibility, environmental resilience, and total cost of ownership. Organizations choosing resin contactors gain a competitive edge through improved system reliability and reduced operational expenses.

The sealed design ensures consistent performance across wide temperature ranges, typically from -40°C to +85°C, making resin contactors suitable for global deployment in any climate. This temperature tolerance, combined with vibration resistance, makes them particularly valuable for mobile and transportation applications.

For engineers and procurement professionals evaluating switching solutions, understanding the fundamentals of DC contactor technology provides the foundation for making informed decisions that optimize both performance and budget.

The Competitive Advantage

Choosing High Voltage DC Contactors with resin construction positions your organization at the forefront of practical innovation. This technology delivers proven performance where it matters most: in real-world applications facing genuine environmental challenges. The combination of robust protection, space efficiency, and economic value creates a compelling proposition for forward-thinking organizations.

As industries continue demanding more from their electrical systems—higher reliability, smaller footprints, better value—resin contactors consistently deliver. They represent not just a component choice, but a strategic decision that impacts system performance, project economics, and long-term competitiveness. Make the smart choice for your next project and experience the resin advantage.

Alexia is the author at Research Snipers covering all technology news including Google, Apple, Android, Xiaomi, Huawei, Samsung News, and More.