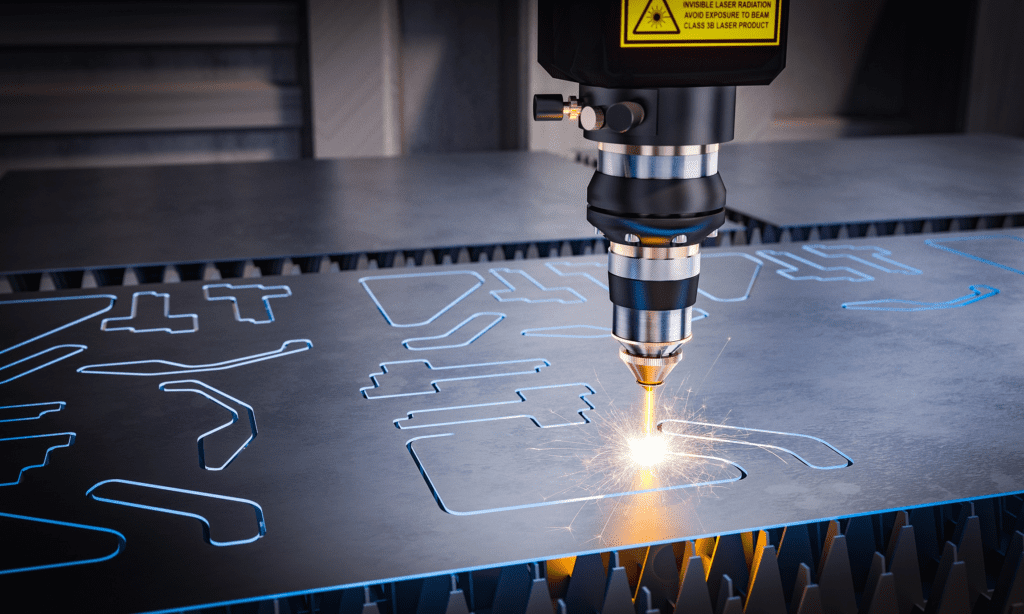

Laser Engraving Materials: Exploring the Possibilities and Limitations

Laser engraving has revolutionized the world of customization and personalization, offering unparalleled precision and versatility. Understanding the possibilities and limitations of laser engraving materials is crucial for achieving outstanding results. In this comprehensive blog post, we will delve into the fascinating realm of laser engraving materials, exploring various options and discussing the creative boundaries they present.

Understanding Laser Engraving Materials

When it comes to laser engraving, the choice of materials plays a vital role in determining the outcome of your project. Let’s explore some of the popular materials that are suitable for laser engraving:

Wood

Wood is a versatile material for laser engraving, offering a natural and timeless aesthetic. Hardwoods like oak, maple, and walnut engrave beautifully, revealing intricate details and depth. Softwoods such as pine and cedar are also suitable for laser engraving, albeit with a lighter and more delicate effect.

Metal

Laser engraving on metal opens up a world of possibilities, allowing for precise markings, intricate designs, and even photographic engravings. Stainless steel, aluminum, and brass are commonly used metals for laser engraving due to their compatibility with the process.

Glass

Laser engraving on glass creates a stunning frosted effect, making it ideal for personalized gifts and awards. From wine glasses to mirrors, the laser can etch intricate designs, names, or even logos onto the surface of the glass, adding a touch of elegance and uniqueness.

Acrylic

Acrylic is a versatile material that offers endless possibilities for laser engraving. It comes in a variety of colors and finishes, allowing for vibrant and eye-catching engravings. From signage to keychains, acrylic is a popular choice for both personal and commercial applications.

Leather

Laser engraving on leather produces exquisite results, enhancing its beauty and adding a touch of personalization. Whether it’s on wallets, belts, or journals, the laser can create precise patterns, monograms, or even intricate artwork, making each piece truly one-of-a-kind.

Plastics

From durable ABS to translucent acrylics, laser engraving on plastics offers versatility in design. Whether it’s engraving serial numbers, logos, or intricate patterns, plastics provide a wide range of applications, including signage, product labeling, and personal accessories.

Possibilities of Laser Engraving

The possibilities afforded by laser engraving are truly limitless. Let’s explore some of the key advantages this technology brings:

Versatility in design and customization:

Laser engraving allows for intricate detailing and precise customization, making it a popular choice for personalizing items such as jewelry, gifts, and promotional products. The laser can reproduce intricate designs, logos, and even photographs, enabling you to create truly unique and personalized items.

High precision and intricate detailing:

Laser engraving offers unrivaled precision, allowing for the creation of intricate and complex designs that would be challenging to achieve with other methods. Fine lines, delicate patterns, and intricate artwork can be etched with exceptional accuracy, ensuring a professional and polished result.

Engraving on curved and uneven surfaces:

Unlike traditional engraving methods, lasers can engrave on curved and uneven surfaces with ease. This versatility opens up a world of creative possibilities, allowing for engraving on cylindrical objects like glassware, bottles, and even rounded jewelry pieces.

Replicating complex artwork and images:

Laser engraving excels at reproducing intricate and detailed artwork, enabling you to replicate complex designs and images on various materials. Whether it’s a famous painting, a cherished photograph, or a detailed illustration, the laser can capture the essence and intricacy of the original, turning it into a tangible and lasting masterpiece.

Limitations of Laser Engraving

While laser engraving offers tremendous possibilities, it’s important to be aware of its limitations to ensure successful outcomes:

Material-specific limitations:

Different materials have specific characteristics that may pose limitations for laser engraving. For example, heat-sensitive materials like certain plastics and fabrics require lower laser power settings to prevent melting or discoloration. Similarly, highly reflective metals may require special coatings or different laser settings to achieve optimal results.

Size and depth constraints:

Laser engraving has certain limitations when it comes to the size and depth of engravings. The laser beam diameter determines the level of detail that can be achieved, so extremely small or intricate designs may require higher laser power or specialized equipment. Additionally, the depth of the engraving is determined by factors such as the power and speed settings, which need to be carefully adjusted for desired results.

Cost considerations for certain materials:

Some materials used in laser engraving can be expensive, such as precious metals or high-quality hardwoods. It’s essential to consider the cost of materials when planning a project to ensure it aligns with your budget and objectives. Exploring alternative materials or optimizing designs can help manage costs while still achieving impressive results.

Home Laser Machines

With the growing popularity of laser engraving, home laser machines have become more accessible. Here are some key points to consider:

The best home laser machines are compact, affordable, and designed for personal use or small-scale projects. They offer a range of features and power options to suit different needs and budgets, making laser engraving accessible to hobbyists and small business owners.

Benefits and limitations of using home laser machines:

Home laser machines provide convenience, allowing users to engrave items from the comfort of their own homes. They offer flexibility in terms of design and customization, empowering individuals to bring their creative ideas to life. However, home machines may have certain limitations in terms of power, engraving area, and material compatibility compared to larger industrial-grade lasers.

Factors to consider when choosing a home laser machine:

When selecting a home laser machine, consider factors such as laser power, engraving area, software compatibility, ease of use, and customer support. It’s essential to choose a machine that aligns with your specific needs and intended applications.

Tips for successful laser engraving at home:

To achieve optimal results with a home laser machine, ensure proper material preparation, adjust laser settings according to the material, and conduct test engravings to fine-tune the settings. Regular maintenance and cleaning of the machine are also important for consistent performance.

Final Thoughts

Laser engraving materials offer a world of creative possibilities, allowing for precise customization and intricate detailing. By understanding the possibilities and limitations of various materials, we can leverage the power of laser engraving to transform ordinary objects into personalized masterpieces. Whether you’re using a home laser machine or working with professional-grade equipment, the journey of exploration and creativity with laser engraving materials is truly awe-inspiring. So, let your imagination soar, push the boundaries, and embark on a journey of laser-engraved wonders.

Alexia is the author at Research Snipers covering all technology news including Google, Apple, Android, Xiaomi, Huawei, Samsung News, and More.