MIT Researchers Develop Shape-Shifting Meta Antenna for Flexible Wireless Tech

Researchers at the renowned Massachusetts Institute of Technology (with) have developed a new antenna that can adapt their frequency ranges by changing their shape. This can save space, material and energy.

Flexible component

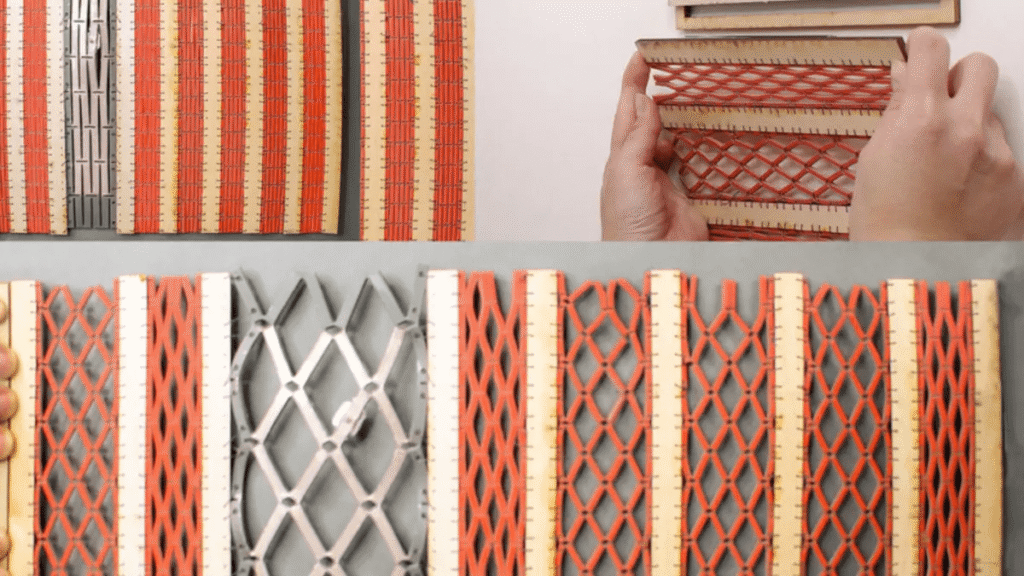

The flexible component, which is known as the “meta antenna”, is based on so -called meta materials – special materials, the properties of which are not determined by the material itself, but by their geometric structure. In contrast to conventional, rigid metal rods, the meta antenna can be deformed. Your resonance frequencies change by bending, stretching or putting together. This allows a single device to support different radio standards. Action range range from wireless energy transmission for portable devices to movement tracking in augmented reality applications to flexible communication technology.

“The special thing about meta materials is that with its geometric structure, the complexity of mechanical systems can be greatly reduced,” said study director Marwa Alalawi, mechanical engineering student on. A prototype already showed that the antenna can move its resonance frequency by 2.6 percent – enough to enable different operating modes in a headphone.

The antenna is manufactured by cutting a rubber seal with a laser and then provided with a conductive coating. In order to ensure durability, the structure also received a flexible layer of acrylic layer. In tests, the construction turned out to be extremely robust: it survived more than 10,000 deformations without damage.

Further development is running

In addition to classic signal transmission, the meta antenna also opens up new possibilities of sensors. Since frequency changes allow conclusions to be drawn about changes in shape, it can register the breathing of a person or react to changed lighting conditions as a “smart curtain”. Applications are also conceivable in the area of wearables: headphones could change solely by deforming noise suppression and transparency mode.

In order to make the technology more accessible, the MIT team has also developed a digital design tool. This allows you to design, simulate, simulate and then to manufacture precisely with the laser. For the future, the researchers are planning three-dimensional variants of the meta antenna, expanded functions for their design tool and even higher material resistance.