The Art and Precision of Investment Casting Manufacturing: A Deep Dive

Investment casting, often known as the “lost-wax process,” is a manufacturing technique that has been honed over centuries, delivering precision-engineered components with unparalleled accuracy and finish. This article delves into the intricate world of investment casting manufacturing, shedding light on its processes, benefits, and the role of a trusted Investment Casting Manufacturer in delivering quality results.

What is Investment Casting?

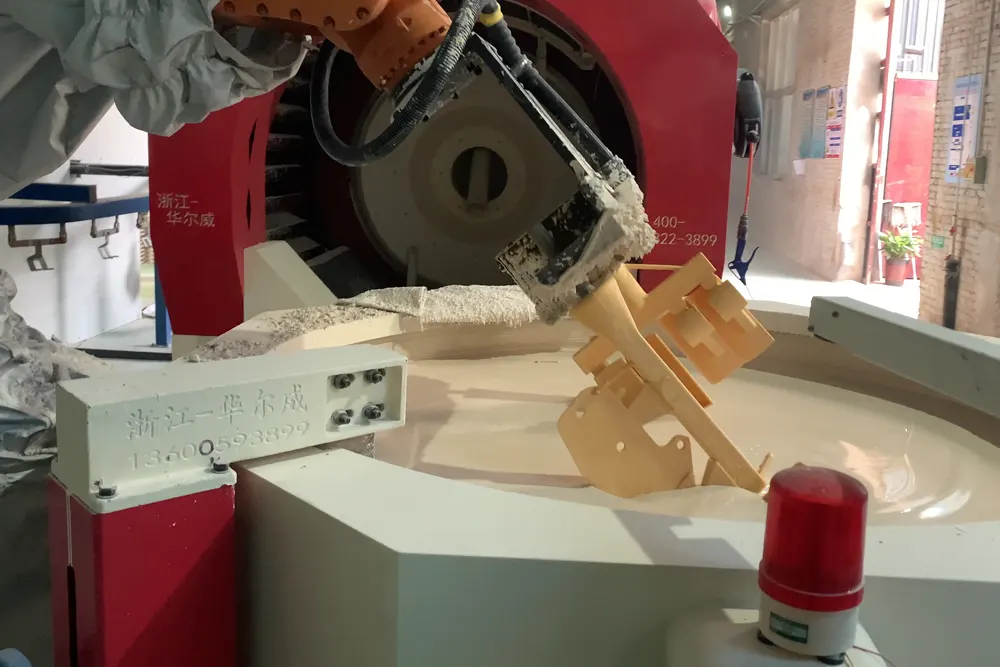

Investment casting is a highly versatile process used to create intricate metal parts with complex geometries. The process involves creating a wax model (or pattern) of the desired part, which is then coated with a ceramic material to form a mold. Once the mold hardens, the wax is melted away, leaving a cavity that is filled with molten metal. After cooling, the ceramic shell is broken away, revealing the finished component.

This process is widely employed in industries such as aerospace, automotive, medical, and energy, where precision and material quality are paramount.

Key Steps in Investment Casting Manufacturing

- Wax Pattern Creation:

The process begins with creating a wax replica of the desired component. High-quality wax is injected into a mold to form the pattern, ensuring accuracy in dimensions. - Assembly of Wax Patterns:

Multiple wax patterns can be assembled onto a single sprue to create a “tree,” optimizing production efficiency. - Ceramic Shell Building:

The wax patterns are dipped into a ceramic slurry and coated with fine sand. This process is repeated multiple times to build a robust shell capable of withstanding high temperatures. - Dewaxing:

The assembly is heated, melting the wax and leaving behind a hollow ceramic shell. - Casting:

Molten metal is poured into the shell, filling the cavity left by the wax. The metal is allowed to cool and solidify. - Shell Removal:

The ceramic mold is broken away, revealing the cast part, which is then cleaned and finished. - Quality Inspection:

Components undergo rigorous inspection to ensure dimensional accuracy and adherence to specifications.

Advantages of Investment Casting

- Complex Geometries:

The process allows the production of parts with intricate designs that would be impossible with other casting methods. - Material Versatility:

Investment casting can work with a wide range of alloys, including stainless steel, aluminum, and superalloys. - High Precision and Finish:

With minimal machining required, investment casting delivers parts with tight tolerances and smooth surfaces. - Reduced Material Waste:

By producing near-net shapes, the process minimizes the need for additional material removal, reducing waste.

Why Choose the Right Investment Casting Manufacture

Selecting a reliable Investment Casting Manufacturer is critical to achieving high-quality results. A reputable manufacturer brings:

- Expertise in Design: Assistance with optimizing designs for manufacturability.

- State-of-the-Art Facilities: Advanced equipment ensures consistent quality and precision.

- Quality Assurance: Comprehensive testing and inspection procedures to meet industry standards.

- Customization Options: Tailored solutions to meet specific requirements, no matter how complex.

Applications of Investment Casting

The flexibility of investment casting makes it suitable for various applications, including:

- Aerospace: High-strength, lightweight turbine components.

- Automotive: Precision parts like gears and exhaust systems.

- Medical: Surgical instruments and implants with exacting standards.

- Energy: Heat-resistant components for power generation.

Conclusion

Investment casting manufacturing is a blend of artistry and engineering precision, offering unmatched flexibility and quality. By partnering with a skilled Investment Casting Manufacturer, businesses can achieve components that meet their exact specifications, paving the way for innovation and performance in their respective industries.

If you’re seeking to bring your designs to life with the reliability and precision of investment casting, look no further than the expertise of an industry-leading manufacturer.

Digital marketing enthusiast and industry professional in Digital technologies, Technology News, Mobile phones, software, gadgets with vast experience in the tech industry, I have a keen interest in technology, News breaking.