Prototype Insert Molding: What It Is, What It’s Used for, and Future Applications

When manufacturers need to produce a limited number of parts with complex geometries, they often turn to prototype insert molding. This process combines the accuracy of injection molding with the flexibility of machining or rapid prototyping methods.

Prototype molding is a rapidly growing field with a wide range of applications. In the medical industry, for example, insert molding is used to create prototypes of implants and other devices. In this blog post, we’ll take a closer look at what prototype molding is, what it’s used for, and some of its potential future applications.

Understanding Prototype Insert Molding

Prototype insert molding is a process that combines the accuracy of injection molding with the flexibility of machining or rapid prototyping methods. This makes it ideal for creating prototypes of parts with complex geometries.

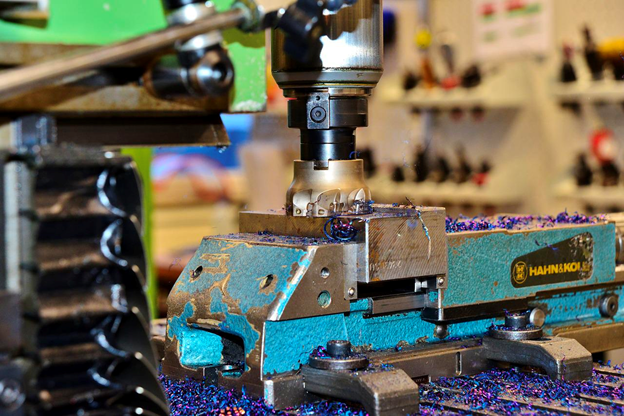

The process begins with the creation of a metal mold. This mold is then used to create a negative of the desired part. Once the negative is created, it can be used to create multiple copies of the part through injection molding.

The major advantage of this method is that it allows for the creation of parts with very intricate designs. The downside is that it can be quite expensive, as the metal mold must be created specifically for each project.

Applications of Prototype Insert Molding

Prototype insert molding has a wide range of applications in various industries, but it is typically used for applications that require high precision, such as electronic components or medical devices. In many cases, it is the only way to achieve the necessary level of accuracy and repeatability.

In the medical industry, for example, insert molding is used to create prototypes of implants and other devices. This allows for the testing of new designs before they are put into mass production.

Another common application is the creation of electronic components. These parts must often be very small and precise, making insert molding the ideal method for their production.

The Future of Prototype Insert Molding

As technology continues to advance, the potential applications of prototype insert molding will only grow. With the ability to create more complex parts, this process will become increasingly important in a wide range of industries:

Medical Devices

In particular, the medical industry is likely to see a continued increase in the use of insert molding. As new designs are developed, this process will allow for the quick and accurate production of prototypes. This will lead to faster development times and lower costs.

3D Printing

3D printing is set to be one of the largest industries of the future. As the technology continues to develop, it is likely that prototype insert molding will play an important role in its growth. The ability to quickly and accurately produce prototypes will allow for the faster development of new designs.

In the 3D printing space, there has been a recent push to develop methods for producing metal parts as well. While this is still in its early stages, it is likely that prototype insert molding will play a role in this development.

Food and Beverage

This process can be used to create prototypes of packaging designs such as cans and bottles. This will allow for faster development and lower costs when introducing new products to market.

Household Products

The household products industry is also likely to see increased use of prototype molding. This process can be used to create prototypes of a wide range of products, from small electronics to furniture.

Summary

Prototype insert molding is a versatile technology with a wide range of potential applications. In the coming years, we are likely to see increased use of this process in a variety of industries.

Digital marketing enthusiast and industry professional in Digital technologies, Technology News, Mobile phones, software, gadgets with vast experience in the tech industry, I have a keen interest in technology, News breaking.